Conductive adhesives, thermal greases , silicone, and conductive inks

Conductive adhesives are formulated with metallic fillers (silver, carbon, copper…) to ensure electrical conduction while providing reliable bonding.

Single and two-component resins are used in numerous electronic encapsulation and protection operations, with processes adapted to each need:

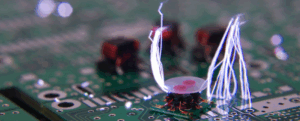

1. Encapsulation

Complete protection of sensitive components against moisture, dust, chemical agents and mechanical shocks.

2. Dam & Fill

Creation of a barrier (dam) to contain a filling resin, ideal for protecting specific areas while ensuring good flatness.

3. Potting

Complete encapsulation in a mold or casing, providing mechanical strength, electrical insulation and heat dissipation.

4. Underfill

Resin injection under SMD components (such as BGAs) to strengthen connections and improve thermal and mechanical reliability.

Benefits :

- Custom packaging: flexibility in supply (in syringes or kits)

- Delivery time (approximately 2 weeks)

- Sampling available for product testing and validation (delivery within 1 week)

- Wide range of products for specific applications

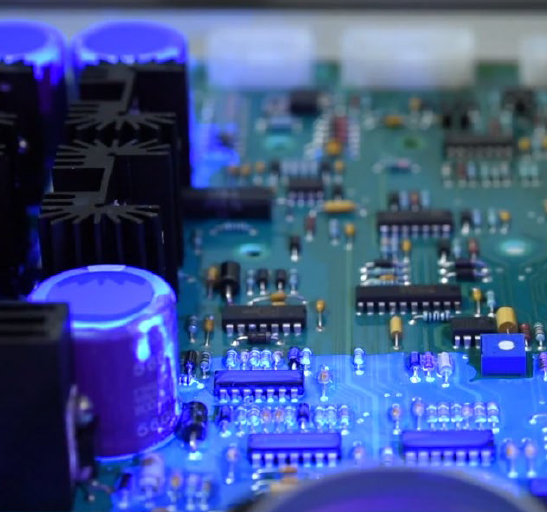

Inks for electronics and printed circuit boards

- Chemical etching reserve ink : Inks specially formulated to protect certain areas of printed circuits or metal parts during a chemical etching process.

- Peelable sparing ink : Used as a temporary mask for brazing, welding, sandblasting or lacquering .

- Traditional two-component and one-component UV-curing photo-imageable shoring ink: High-resolution inks for precise applications with photolithographic processes.

- UV-curing printed circuit board marking ink : Formulated to print information directly onto PCBs: batch numbers, logos, markers, components, etc.

Benefits :

- Chemical and mechanical resistance

- Custom packaging

- Custom development

Galden®, Inventec® and TMC Industries®: Heat transfer fluids for leak testing and thermal shock

1. Thermal management of electronic components

- Cooling of high-power components (IGBT, LED, ASIC)

- Embedded printed circuits, radar, communication, defense

- Integration into liquid-cooled or immersion systems

2. Leak tests (fine sealing, helium leak or pressure)

- Use as a neutral and stable medium , compatible with sensitive sensors

- Enables the detection of micro-leaks in electronic or hermetic components (capsules, MEMS sensors, batteries, etc.)

3. Thermal shock testing

- Fluid used in temperature-controlled tanks (from -70 °C to +200 °C depending on the fluid)

- Rapid transition between two thermal baths to validate the robustness of the assembly

- Common method in standardized tests for electronic components (MIL-STD, IPC-TM-650…)

Benefits :

- Galden® is ideal for environments requiring extreme temperatures and electrical insulation.

- Inventec® is suitable for high-performance cooling applications where viscosity and fluidity are important.

- TMC Industries® offers more specialized solutions, adapted to robust and durable fluids.

Product or surface preparation before dosing

The preparation phase determines the final performance of the assay (adhesion, polymerization, homogeneity). It is divided into two main categories:

- Product preparation (homogenization, degassing)

- Surface preparation (cleaning, activation, decontamination)

Our solutions:

- Planetary mixer

- Charging/discharging and antistatic dust removal

- Atmospheric plasma (torch) or vacuum plasma (chamber) for cleaning, activating, and etching substrates

Why include these steps?

- Reduction of non-conformities (bubbles, poor wetting, peeling)

- Process optimization : fewer rework, better reliability

- Improvement of final performance : adhesion, insulation, polymerization

- Traceability and reproducibility (automated systems)

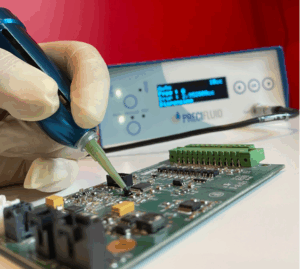

Single and two-component assay

- Time-pressure and volumetric dosing units

- Pistols

- Syringes / pistons / caps / stoppers

- Static mixers

- Cartridges

- PPG/Semco® range

Automated/robotic dosing

- 3 and 4 axis table and gantry robots

- Dosing valves (jetting, high pressure, single and two-component volumetric,…)

- Dosing and two-component mixing systems

- Flange, mounting and safety cover

- Automated PVA dosing system : standalone or inline for tropicalization, encapsulation, dam & fill, potting, underfill

Post-Dosage

- Polymerization systems for UV resins, inks and adhesives

- Mercury or LED lamps

- Point or surface sources

Choose adhesives, inks and equipment from the RG distribution group

- Review of specifications and proposal of a customized technical solution

- A single supplier and point of contact for the entire range

- All equipment maintenance can be carried out by our specialist technicians.

- Specialized,

short lead time - Competitive prices

- ISO 9001 certified group